12 Treatment Technologies

The PFAS Team developed a Treatment Technologies training module video with content related to this section.

Treatment technologies for PFAS in environmental media are still evolving and it is prudent to use caution in implementing long-term remedies. Selection of remedial actions should prioritize protection of drinking water sources and human health, with consideration of other objectives (such as reducing risk to ecological receptors and environmental resources, liability, source area mass, mass flux, generation of PFAAs from precursors). At some sites, it might be reasonable to take short-term site actions that address impacted or threatened receptors with the intent of applying more robust and cost-effective technologies as these are developed.

The treatment technologies described in this section are organized into three categories by degree of development and implementation: field-implemented technologies, limited application technologies, and developing technologies. The criteria for each category are further described below.

12.1 Overview

Treatment technologies exploit a contaminant’s chemical and physical properties to immobilize, separate and concentrate, or destroy the contaminant. The physical and chemical properties of PFAS make many treatment technologies ineffective, including those that rely on contaminant volatilization (for example, air stripping, soil vapor extraction) or bioremediation (for example, biosparging, biostimulation, bioaugmentation). Even technologies such as thermal treatment and chemical oxidation may not be completely effective at treating PFAS, and multiple treatment technologies may be needed for each treatment scenario to address the mixture of different PFAS that may be present.

Treatment technologies can be employed either ex situ or in situ. For example, when groundwater is extracted via pumping from wells and treated, this would be considered an ex situ approach. In contrast, when treatment materials are injected into the subsurface to separate, destroy, or immobilize contaminants in groundwater under the surface, this would be considered an in situ approach. Many existing treatment technologies have generally been shown to be inadequate; therefore, the unique chemical properties of PFAS often require new technologies or innovative combinations of existing technologies.

A range of technologies exists for treatment of either liquids or solids that may be performed either in situ or ex situ. However, field-implemented technologies for treating PFAS in liquids are mostly limited to ex situ technologies.

Field-implemented full-scale treatment of PFAS-impacted liquids or solids is limited to sequestration technologies that remove or bind PFAS but do not destroy them. Sorption using granular activated carbon (GAC) and ion exchange (IX) media has been proven effective at full scale (see Table 12-1 Treatment Methods Table Excel File). Destruction and mineralization technologies, including bioremediation, chemical oxidation, chemical reduction, and thermal technologies, are being tested. This section discusses treatment technologies for liquids (waters, leachates, or other liquid wastes) and solids (soil, sediment, or other solid wastes).

The treatment technologies described in this section are organized by the degree of development and implementation documented in practice or in peer-reviewed literature, regulatory acceptance, and a consensus process. A consensus for the ranking of each technology is determined by the best professional judgment of members of the ITRC PFAS team after evaluating the current information and considering input from other external parties during regular reviews of the document. The three levels used in this discussion are field-implemented technologies, limited application technologies, and developing technologies.

Although categorized in this way for this document, the state of development and application of treatment technologies is a continuum that is ever-changing and evolving quickly. Technologies may progress through these categories between revisions of this guidance document. Most important is that by categorizing, ITRC neither endorses nor repudiates any technology or its proponents regardless of its state of development. Each technology should be evaluated independently to determine the applicability of the technology for the site conditions and desired treatment objectives. The three categories are:

1) Field-implemented technologies –Technologies that have been demonstrated at multiple sites, under diverse conditions, by multiple practitioners, are commercially available, and are well documented in practice or peer-reviewed literature. Field-implemented technologies have been demonstrated to meet site-specific PFAS treatment objectives, at the intended final application scale, and are widely accepted in the regulatory and scientific community.

2) Limited-application technologies –Technologies that have been implemented on a limited number of sites, by a limited number of practitioners, either at full-scale or field pilot-scale. For this document, full-scale is defined as operation of a fully capable system, intended to entirely address the appropriate aspects of the remedial action objectives (RAOs) for the treated media, and which is not intended to be expanded or supplemented in the future to achieve those final project goals. Field pilot-scale refers to a demonstration project intended to prove the effectiveness of the treatment technology in the field, under site conditions. While these projects may not address the RAOs explicitly or completely, these demonstration projects typically involve continuous operation over months of activity, with robust analytical monitoring, and published results in the peer-reviewed literature. Limited application technologies are supported by a growing body of evidence that they are effective at treating PFAS, but differ from full-scale implemented solutions in that there may not yet be a large body of evidence or broad consensus in the scientific community, including peer-reviewed literature, that the technology meets the criteria for a field-implemented technology. Limited-application technologies for liquids and solids are contained in the Table 12-1 Treatment Methods Table Excel File and discussed in Sections 12.6 and 12.7.

3) Developing technologies –Technologies that have been researched at the laboratory or bench scale. Often, the results from developing technologies are reported by only one group (for example, one university, practitioner, or vendor) or lack detailed independent verification of the treatment effectiveness or mechanisms. Among a wide array of experimental technologies under development, only developing technologies that show promise and have some level of publicly available documentation demonstrating effectiveness are included in this guidance document.

The technology evaluations presented herein provide information on the effectiveness of each treatment technology. This information varies widely among technologies and the data provided are based on the reported test conditions and results. Ultimately, the feasibility of a technology to meet applicable regulatory guidance values and standards often depends on site-specific conditions.

As detailed in Section 8.2.2.4, in the United States, the regulatory standards for PFAS treatment are primarily driven by drinking water mitigation and focused on a small subset of PFAS. PFOS, PFOA, PFBS, and HFPO-DA are the only compounds with federal health advisories (USEPA 2022), and most regulatory discharge criteria for PFAS focus on these compounds. In 2023, USEPA proposed the National Primary Drinking Water Regulations (NPDWRs) containing MCL and MCLG values that are currently under public review (USEPA 2023). Some states have guidelines, and several have regulatory criteria for additional PFAS, but precursor and short-chain PFAS are generally not considered in regulations or guidance, although that is beginning to change. The technology evaluation information presented here provides data about all PFAS tested for a given technology. This information varies widely among technologies. Additional information on regulations is provided in Section 8 and the PFAS Regulatory Programs Summary Excel File.

12.1.1 Factors Affecting Technology Selection

Selection of a remedy, with confidence that treatment targets can be achieved, depends on several key factors, including the ability to reliably define the nature and extent of contamination, the availability of proven treatment technologies, and the capacity and tools to measure progress and compliance with desired regulatory criteria. A well-prepared conceptual site model (CSM) requires adequate information and is also fundamental to understanding and presenting the rationale and justification for the selected remedy. Additional information on CSMs is provided in Section 2.6, Section 9, and Section 10.

Moreover, proven treatment technologies are limited in capacity and demonstrated ability to meet chosen treatment targets. The comprehensive discussions contained herein reveal many questions and uncertainties that must be addressed.

As an example, factors affecting PFAS remedy selection can include:

- characteristics of PFAS. The wide-ranging chemical and physical characteristics of PFAS affect the treatment effectiveness. Key factors include recalcitrance with respect to common technologies due to the strength of the carbon-fluorine bond, ionic state (anionic, cationic, and zwitterionic), types of ionic groups (sulfonate or carboxylate), lipo- and hydrophobicity, chain length and branching, partitioning coefficients, phase behavior, volatility, solubility, acidity, total PFAS mass, and total concentration.

- changes in PFAS properties. Naturally occurring processes or remedial actions for other (commingled) contaminants, such as chlorinated solvents and petroleum hydrocarbons, can affect PFAS distribution and mobility in groundwater (McGuire et al. 2014). Example changes include:

- The alkyl functional group of some PFAA precursors may be more readily subject to chemical or biological transformation than the fully fluorinated aliphatic chain (PFAAs).

- Partial degradation of the carbon-carbon bonds in the aliphatic chain reported for some chemical remedies generates short-chain PFAS, which may be more mobile (Guelfo and Higgins 2013).

- Modifications in aquifer properties (for example, redox or pH) during remediation of commingled contaminants results in a conversion of some precursors to the more stable and mobile PFCAs (McKenzie et al. 2015; McKenzie et al. 2016).

- co-contaminants, organic matter, and geochemistry. The presence of co-contaminants, total organic carbon, natural organic matter, minerals, and anions can significantly affect remediation. Some technologies that are designed and implemented to treat PFAS co-contaminants may transform perfluoroalkyl acid (PFAA) precursors into more stable perfluorocarboxylic acids (PFCAs) (McKenzie et al. 2015).

- community acceptance. Stakeholders, including community members, are often faced with trade-offs in terms of cost, level of cleanup, and residual contamination as part of remediation efforts.

An additional element of technology selection relates to the optimal conditions under which a specific technology should be considered, as documented in the literature. Not all technologies have been demonstrated as suitable or effective under multiple treatment circumstances. For example, although sorption technologies, such as granular activated carbon or ion exchange media, have been documented in the literature as being both technically effective and generally cost-effective in treating high volume, low concentration liquids, such as drinking water, they are less well suited for low volume, high concentration liquids such as thermal system condensate, ion exchange regeneration fluids, fractionated (for example, reconstituted) foam, or landfill leachate. Conversely, several destructive technologies, such as electrochemical oxidation, nonthermal plasma, hydrothermal alkaline treatment, and supercritical water oxidation, have been shown to be effective for treatment of high concentration, low volume liquids, but may be less suitable for high volume, low concentration liquids. See Section 12.1.4 for considerations for specific environmental media.

For those directly engaged in assessing the suitability of PFAS treatment technologies, a structured process for systematic evaluation is currently under development via a Strategic Environmental Research and Development (SERDP)-funded project (ER18-1633). The project focuses on five lines of evidence to evaluate technology performance and will provide resources to identify relevant information and data gaps and address key questions necessary for that assessment. Additional information is provided in Section 12.9.

12.1.2 Tiered Remedial Approach

Along with the factors affecting technology selection (Section 12.1.1), practitioners should also consider the use of a tiered remedial approach to mitigate the risks posed by PFAS. This may include prioritizing protection of known human receptors from exposure to drinking water contaminated by PFAS by using point of entry (POE) or point of use (POU) treatment systems or connecting residents to public water supplies. Reducing the potential risk to human and/or ecological receptors may require upgrades to wastewater treatment plants; however, large-scale retrofits of wastewater treatment plants for PFAS have not been widely enacted at this time. Once these actions are taken to control risk and exposure, the source(s) of the PFAS contamination can be addressed using the appropriate remedial technology. Cutting off sources and controlling ongoing contaminant flux will influence whether PFAS plumes becoming stable or shrink. Once sources and pathways to receptors are controlled, addressing the pathways of contaminant migration (for example, groundwater plumes, stormwater drainage networks, surface water) becomes the final aspect of the tiered approach. A similar approach for site characterization is described in Section 10.2.

12.1.3 Section Organization

The information presented in the following sections reflects the availability of performance results published, presented, or otherwise publicly available. Those technologies that have been implemented in the field at multiple sites, by multiple parties, and have peer-reviewed or practical documentation of performance are discussed in Section 12.2 and Section 12.3. Projects funded by SERDP and the Water Research Foundation (WRF) are also highlighted. This section discusses the following key elements for each of these field-implemented technologies:

- treatment description–background and development of technology

- treatment mechanism–separation, sorption, or destruction

- state of development–applications and degree of commercial availability

- effectiveness–documented treatment effectiveness on PFAS and common co-contaminants along with water quality considerations and pretreatment need and options

- design/operating considerations –critical or unique operational or design needs

- sustainability–footprint, community enhancement, and cost.

Treatment case studies are presented in Section 15.2.

12.1.4 Considerations for Specific Environmental Media

12.1.4.1 Drinking Water

Public-serving system components are often required to be certified through NSF 61 (https://www.nsf.org), which certifies that they are acceptable for potable water use. Treatment for PFAS in these systems typically uses adsorbents such as GAC (Section 12.2.1.1), IX (Section 12.2.1.2), or RO (Section 12.2.2).

Remedial actions for PFAS-impacted drinking water from private wells and other nondistributed sources can include providing alternative drinking water supplies, such as bottled water, new nonimpacted source wells or surface water, point of entry (POE) treatment (also referred to as POET), and point of use (POU) treatment. POE treats water as it enters a home or building (for example, immediately after a pressure tank for a private well system) and POU treats water at one or more specific locations (for example, at a kitchen faucet where water is typically directly ingested or used for cooking). POE systems provide “whole supply” treatment while POU provides selected usage point treatment.

NSF International has incorporated PFOA and PFOS into two standards – NSF/ANSI 53 for adsorption systems and NSF/ANSI 58 for reverse osmosis systems – to verify the ability of a water treatment device to reduce PFOA and PFOS to achieve the USEPA health advisory levels of 70 ng/L (NSF 2021; NSF 2019). This method does not evaluate the removal of other PFAS that also may adversely impact water supplies. Systems with this certification are mainly small-scale POU systems such as sink faucet filters, refrigerator water filters, and pour-through filters. It should be recognized that although this certification exists, it is not required. This means that other POU systems as well as POE systems (larger wellhead or large public-serving systems) may not be certified under NSF/ANSI 53 or NSF/ANSI 58 but may be acceptable treatment of PFOA and PFOS.

12.1.4.2 Landfill Leachate

Currently, a majority of landfill leachate is treated for conventional constituents by directly discharging or hauling the leachate to publicly owned treatment works (POTWs). POTWs have been designed to remove these conventional constituents (for example, organics and nutrients), but these treatment systems are not effective at removing PFAS. A relatively small percentage of landfills perform pretreatment to address conventional parameters (for example, BOD, COD, TSS, ammonia-N) prior to discharging to POTWs or perform leachate treatment on-site and discharge the treated effluent under National Pollutant Discharge Elimination System (NPDES) permits. There are currently very few landfills that treat or pretreat leachate specifically to remove PFAS, but this may change as national and state surface water and/or pretreatment regulations are developed.

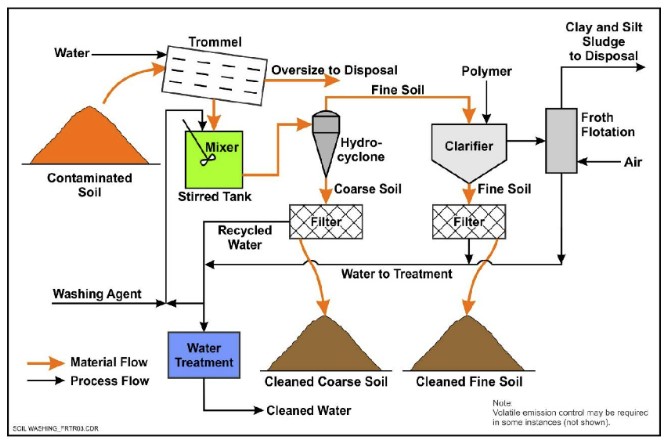

Wei, Xu, and Zhao (2019) presented a comprehensive review of the state of the science on PFAS treatment technologies for landfill leachate. They noted that various technologies have been widely tested for treating PFAS in drinking water or groundwater, but knowledge is limited on the treatability of PFAS in landfill leachate and the effects of the complex leachate matrix. Leachate contains many competing organic and inorganic constituents, and this complex matrix creates significant challenges when choosing a treatment technology for PFAS removal. Oftentimes, pretreatment of the leachate may be required before applying common PFAS sorption technologies such as GAC or ion exchange resins. If pretreatment is not performed to remove these competing compounds, the sorptive treatment media will foul quickly, which may result in operationally complex and/or expensive systems to treat landfill leachate for PFAS using these traditional technologies. Additional information on integrated remedial solutions is presented in Section 12.8.

Destructive technologies such as plasma, advanced oxidation, reduction, photochemical processes, and sonolysis are largely unproven at present on landfill leachate, and their effectiveness is expected to be reduced when used for treating leachate due to the severe water matrix effect (Wei, Xu, and Zhao 2019). In addition, these technologies have typically not been as effective when scaled up from laboratory studies to the field. Supercritical water oxidation (SCWO) destruction of landfill leachate containing PFAS has been demonstrated but is not well documented in peer-reviewed literature. More information about SCWO is included in Section 12.6.3.12.

Filtration systems such as RO have been proven effective as a separation technology for leachate for a wide range of constituents, including PFAS, but can generate a significant fraction of concentrated residuals that requires management by other disposal/treatment technologies. Foam fractionation shows promise in recent studies for selectively separating large percentages of PFAS from leachate (particularly the longer chain PFAS) while generating manageable fractions of high concentration residuals at a much smaller volume relative to RO reject (Burns et al. 2022; McCleaf, Kjellren, and Ahrens 2021; Robey et al. 2020; Smith et al. 2022).

Overall, further research is needed to develop and demonstrate cost-effective treatments for landfill leachate PFAS removal that are effective at field scale.

12.1.4.3 Biosolids

Biosolids generated by wastewater treatment plants have been historically managed through land application, use or disposal at landfills, or incineration. The regulatory landscape for management of biosolids is evolving, and some states have started to require testing, prohibit land application if concentrations of certain PFAS are greater than specific levels, or have implemented bans on land application. Current regulations and guidance are discussed in Section 8 and in the PFAS Regulatory Programs Summary Excel File.

Incineration is a topic of current study to better understand the fate of PFAS due to possible incomplete combustion and byproduct generation (USEPA 2020) and is covered in more detail in Section 12.4.

Additional information on biosolids is presented in the ITRC factsheet for Biosolids and Per- and Polyfluoroalkyl Substances (PFAS) (/fact-sheets/) and Section 2.6.4.

12.2 Field-Implemented Liquids Treatment Technologies

These technologies have been implemented in the field by multiple parties at multiple sites and the results have been well-documented in practice or peer-reviewed literature. The liquid treatment technologies in this section may be applied to a variety of PFAS-impacted media, including drinking water (regardless of source), surface water, groundwater, wastewater, stormwater, or landfill leachate. Not all technologies would be appropriate for all applications. Site-specific evaluation is necessary to identify the best technology alternative for a given liquid, system size, treatment goal, and residual media management scenario.

12.2.1 Sorption Technologies

Sorption technologies have been used for both ex situ and in situ water treatment applications. Multiple sorption media types may be used in series for ex situ applications to optimize overall concentration reduction and removal capacity. Adsorption and ion exchange (IX) are two “sorption” mechanisms by which PFAS can be removed from water. Adsorption is a physical mass transfer process that uses Van der Waals and/or other weak ionic forces to bind the entire PFAS molecule to the surface areas of the adsorptive media. Ion exchange is the exchange of ions of the same charge. Ion exchange targets and binds to the hydrophilic ionized or functional end of the molecule (for example, the sulfonate in PFOS) while releasing an equivalent amount of an innocuous ion (for example, chloride) into the treated water. This technology is generally considered more applicable to high volume, low concentration liquids than low volume, high concentration liquids.

Several influent water parameters can therefore be expected to impact the sorption efficiency for a specific PFAS. These include pH, ionic strength, the nature and concentrations of organic co-contaminants present (including naturally occurring organic matter [NOM]), competing inorganic ions normally present (for example, sulfate, nitrate, bicarbonate, and chloride), and any suspended solids, potentially precipitating impurities (for example, iron, manganese, calcium carbonate), or biological growth that can foul and degrade the performance of the media. Pretreatment steps may be necessary to optimize the performance of such media, including coagulation, precipitation, filtration, pH adjustment, or oxidant removal. Ion exchange media used for PFAS removal from water use both the adsorption and ion exchange mechanisms. The use of two or more different media in series can be considered if the expected increase in overall removal efficiency can be used to justify the increased equipment cost.

Life cycle cost assessments can be used to compare the long-term cost-performance benefits of various sorption media types. Spent media management can be an important consideration when selecting a treatment technology. Common options for spent media management are off-site disposal by thermal destruction (via commercial incineration or cement kilns), reactivation/regeneration for reuse (which may require management of additional waste streams), and landfilling. Information on specific management considerations for spent media are discussed in the respective sections below.

Incineration and thermal reactivation/regeneration offer the possibility of destruction of PFAS waste streams, though incineration has received recent attention due to possible incomplete combustion and by-product generation and is the topic of current study to better understand the fate of PFAS. Incineration is discussed in Section 12.4.

Related Past, Ongoing, and Recent Research Funded by SERDP (ER) and Water Research Foundation (WRF)

- ER18-1395 Electrically Assisted Sorption and Desorption of PFASs

- ER18-1417 Molecular Design of Effective and Versatile Adsorbents for Ex Situ Treatment of AFFF-Impacted Groundwater

- ER18-1052 Remediation of PFAS Contaminated Groundwater Using Cationic Hydrophobic Polymers as Ultra-High Affinity Sorbents

- ER18-1306 Combined In Situ/Ex Situ Treatment Train for Remediation of Per- and Polyfluoroalkyl Substance (PFAS) Contaminated Groundwater

- ER18-5015 Removal and Destruction of PFAS and Co-contaminants from Groundwater via Groundwater Extraction and Treatment with Ion-Exchange Media, and On-Site Regeneration, Distillation, and Plasma Destruction

- ER18-B3-5053 Evaluation and Life Cycle Comparison of Ex-Situ Treatment Technologies for Poly- and Perfluoroalkyl Substances in Groundwater

- WRF 4913 Investigation of Treatment Alternatives for Short-Chain PFAS

- ER21-1191 Determination of Thermal Degradation Products and Residuals of Per- and Polyfluoroalkyl Substances-Laden Sorbent Materials in Gas and Condensed Phases

- ER21-1238 Sustainable PFAS Treatment Using Layered Double Hydroxide (LDH) Sorbents

- ER20-5182 Validation of Colloidal Activated Carbon for Preventing the Migration of PFAS in Groundwater

- ER18-1026 Rational Design and Implementation of Novel Polymer Adsorbents for Selective Uptake of Per- and Polyfluoroalkyl Substances from Groundwater

- ER20-5252 Anion Exchange Permeable Adsorptive Barriers (PABs) for In Situ PFAS Immobilization and Removal

- ER20-5100 In Situ PFAS Sequestration in AFFF-Impacted Groundwater

- ER21-1185 Thermal Decomposition of PFAS on GAC: Kinetics, Mass Balance, and Reuse of Reactivated Carbon

- ER21-1256 Develop Synergetic Novel Macrocycle-based Sorbents with Thermal Destruction for Enhanced PFAS Removal in Groundwater and Drinking Water Treatment

- ER21-1124 Assessment of Long-Term Effectiveness of Particular Amendments for In Situ Remediation of PFAS in Mixed Plumes

- ER22-3150 Engineering an “All-In-One” Biochar-Surfactant System for Enhanced PFAS Sorption and Reductive Degradation Using a Coupled Ultraviolet and Ultrasonication Approach

- ER22-3155 In Situ Sequestration of PFAS from Impacted Groundwater using Injectable High Affinity Cationic Hydrophobic Polymers

- ER22-3415 Novel Swellable Ionomers for Enhanced PFAS Sorption and Destruction

- ER22-7363 Rapid and Inexpensive Delivery of Particulate Carbon for In Situ PFAS Treatment in Groundwater

- ER22-3119 High-Capacity Sustainable Sorbents for Treatment of PFAS

- ER22-3194 Green Remediation of PFAS in Soil and Water

12.2.1.1 Granular Activated Carbon (GAC)

Treatment Description: GAC is an effective sorbent media for organics that has historically been used to reduce contaminants in a variety of environmental media. The information contained in this section describes ex situ GAC treatment in which water is extracted and transferred from the source of contamination and directed through the treatment system.

Treatment Mechanism: Removal of PFAS by GAC is a physical mass transfer process (refer to Section 12.2.1) from the aqueous phase onto solid media that does not involve or trigger any form of chemical degradation or transformation.

State of Development: The application of GAC as a treatment technology for PFAS removal has been practiced for over 15 years at more than 45 military installations, as well as several industrial sites and publicly owned treatment works (Forrester 2018) involving private and municipal drinking water supplies.

Effectiveness: The following references were used to support the treatability effectiveness discussion presented below for PFAS by GAC: Appleman et al. (2013); Burdick et al. (2016); Cummings (2015); Dickenson (2016); Ochoa-Herrera and Sierra-Alvarez (2008); Szabo (2017); Woodard, Berry, and Newman (2017); Zeng et al. (2020). These references also include more comprehensive bibliographies if further details are needed on specific topics or studies. Literature and supporting column studies have shown that newly placed GAC can reduce effluent concentrations for PFAS listed in USEPA Method 537.1 (Shoemaker and Tettenhorst 2018) to below analytical detection limits until initial breakthrough begins to occur. Because GAC is generally used to treat many common groundwater contaminants, it is capable of also treating most organic co-contaminants that may be present, with the primary impact being increased GAC consumption due to greater loading per unit of time, which may require more frequent change-outs.

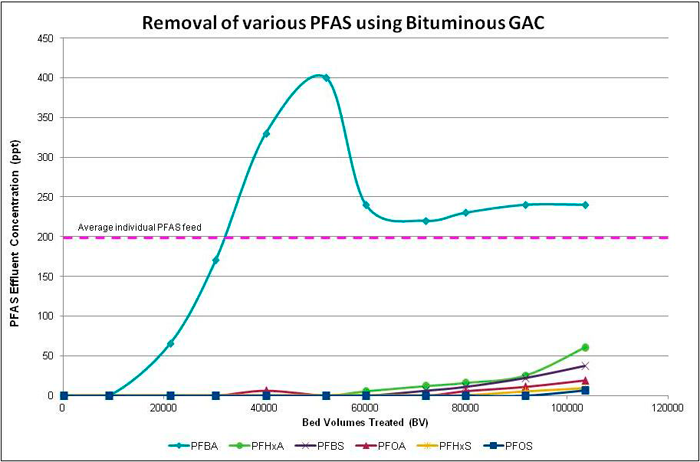

Individual PFAS have different GAC loading capacities and corresponding breakthrough times (often defined as the number of bed volumes treated prior to detection in the effluent) (Eschauzier et al. 2012; Zeng et al. 2020). GAC removal capacity for PFOS is greater than PFOA, but both can be effectively removed (McCleaf et al. 2017). In general, shorter chain PFAS have lower GAC loading capacities and faster breakthrough times, but could be effectively treated if change-out frequency is increased. Figure 12-1 provides an example of removal curves and breakthrough information for several PFAS performed at a specific influent concentration based on vendor-supplied column studies.

Figure 12-1. Example GAC removal curves at specific influent concentration (15-minute empty bed contact time).

Figure 12-1. Example GAC removal curves at specific influent concentration (15-minute empty bed contact time).

Source: Used with permission from Calgon Carbon Corporation.

More studies are needed to confirm GAC treatment effectiveness for shorter chain PFAS or to identify complementary technologies/materials to supplement GAC removal capability. This may include studying the influence on sorption site competition from PFAS precursors that are often not quantified during the GAC system design. Recent accelerated column tests by vendors have shown the successful removal of a variety of PFAS, including the butyl (C4), pentyl (C5), and hexyl (C6) compounds (Appleman et al. 2013; Dickenson 2016; Brewer 2017; Zeng et al. 2020). Functional groups also impact the ability of GAC to adsorb PFAS. Compounds with sulfonate and sulfonamide groups are more readily adsorbed than those with carboxylates of the same chain length (Appleman et al. 2013; Dickenson 2016; Zeng et al. 2020). Studies in the developmental stage involve the use of other materials that can modify GAC surfaces to improve removal capabilities. Mixtures of powdered activated carbon, kaolinite, and amorphous hydroxide have been tested at the bench- and pilot-scale and have shown high removal rates for shorter chain PFAS in raw AFFF-impacted groundwater (Chiang 2017; Kempisty, Xing, and Racz 2018).

Most of the case studies on full-scale GAC-based systems used to treat PFAS in the literature are based on treatment of PFOA and PFOS in impacted drinking water sources. As such, limited information is available regarding the treatment of other PFAS, or PFAS in other source waters. The full-scale drinking water systems demonstrate that PFOA and PFOS can be removed to below analytical detection limits. More information is contained in the Table 12-1 Treatment Methods Table Excel File. Treatment of groundwater impacted with PFAS from an AFFF release area contaminated with PFAS such as fire training areas (FTAs) may require complex pretreatment and more frequent change-outs (higher influent concentrations compared to influent for drinking water treatment systems) and higher operation and maintenance (O&M) costs.

Design/Operating Considerations: Laboratory treatability tests (for example, rapid small-scale column testing (RSSCT) and accelerated column test (ACT)) are useful for evaluating treatability and determining initial design parameters. Larger scale pilot demonstrations are recommended to establish site-specific design parameters such as adsorption bed depth; GAC consumption rate to meet a given treatment objective; empty bed contact times (EBCTs); projections of breakthrough (based on bed volumes treated); and corresponding change-out frequency/costs. Column studies can also be used to compare loading capacity/breakthrough performance for different types of GAC (for example, different materials, preparation methods, and pore size distributions) offered by various vendors. These studies should always use site water to ensure that the effects of site-specific geochemical characteristics are assessed. Alternative analytical screening methods, for example, total oxidizable precursor (TOP) assay (Section 11.2.2.2), adsorbable organic fluorine (Section 11.2.2.4), and particle-induced gamma ray emission (PIGE) (Section 11.2.2.3), can be used to better estimate potential total mass load during the GAC remedial design phase. Field performance of GAC systems often varies significantly from that predicted in the RSSCT and other bench tests. Proper monitoring is critical to demonstrate that the desired performance is being achieved, especially at system start-up and following media change-out events.

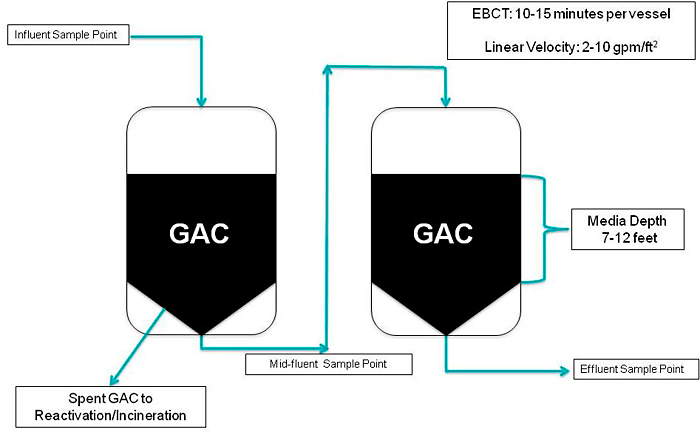

Temporary and permanent GAC systems can be rapidly deployed and require minimal operator attention, if intensive pretreatment is not needed. The GAC media are placed in packed-bed flow-through vessels generally operated in series (lead-lag configuration). EBCTs of 10–20 minutes per vessel are typical (AWWA 2019). PFAS breakthrough is monitored by testing the water, at a minimum, between the lead and lag vessels. Additional sampling ports can be added (for example, at 25%, 50%, and 75% of the depth of the media). When breakthrough exceeds identified change-out criteria, the lead bed is taken offline and the spent GAC is removed and replaced with either new or reactivated GAC. The spent media are disposed off site by thermal destruction or can be thermally reactivated for reuse. Treatment can be continuous if the lag bed is used as the lead bed while the media in the latter are changed out. Figure 12-2 depicts a simple process flow diagram for a GAC treatment system.

Figure 12-2. Typical GAC treatment system process flow diagram.

Figure 12-2. Typical GAC treatment system process flow diagram.

Source: Used with permission from Calgon Carbon Corporation.

Various GAC base materials (for example, bituminous coal, lignite coal, coconut shells) can be used for adsorption, though bituminous coal-based GAC has been used for the majority of existing sorption treatment systems for PFAS and current data show that bituminous-based products are more effective for PFAS removal (McNamara et al. 2018; Westreich et al. 2018). Specialized GAC formulations and coconut-based GAC can also be effective. Media selection and life cycle cost will depend upon a number of factors, including PFAS and co-contaminant concentrations, media availability, and pricing.

GAC treatment applications will evolve as analytical methods improve and regulatory concerns encompass an increasing number of PFAS. Shorter chain PFAS exhibit faster breakthrough times (Appleman et al. 2013), so particular attention needs to be given to these compounds if their removal is required. Alternative design optimization approaches or use of other technologies in combination with GAC (for example, ion exchange (IX) resins discussed in Section 12.2.1.2) can address high O&M costs that can be incurred for GAC treatment involving high influent PFAS concentrations, especially if shorter chain PFAS must be removed. As discussed in Section 12.2.1.2, specialty single-use and regenerable IX resins have been developed that have higher loading capacities for shorter chain PFAS. GAC and IX can also be used in series to optimize removal capacity and minimize O&M costs, generally with GAC ahead of IX to remove non-PFAS organics and longer carbon chain PFAS, followed by IX to remove the shorter carbon chain PFAS. This approach has been implemented in the field and is presented in a case study in Section 15.2.2.1.

Spent GAC that contains PFAS can be thermally reactivated and reused, which may result in a lower cost media replacement option versus new GAC. However, some regulatory agencies may not allow the use of reactivated GAC for drinking water systems. NSF/ANSI standards require that the use of reactivated GAC for drinking water systems involve only media generated by the treatment system owner/operator and cannot include a mixture of GAC that originated from other sources. The management of spent media should be planned during the life cycle assessment phase and be documented as the treatment system is executed. Commercial facilities are available for thermal reactivation of spent GAC, which currently are not available for other sorption media and can offer a potential life cycle cost benefit for spent media disposal. Based on vendor feedback (Mimna 2017), commercial thermal GAC reactivation is performed at higher operating temperatures than steam or nitrogen regeneration systems, and may be capable of complete desorption and destruction of PFAS from spent GAC (Watanabe et al. 2016; Yamada et al. 2005). However, similar to incineration, additional studies are needed to investigate the fate of PFAS in the GAC reactivation process.

Sustainability: GAC ex situ PFAS water treatment systems have unique sustainability considerations as well as considerations in common with other ex situ PFAS sorption media water treatment systems (treatment complex construction, utilities, water collection and pumping, and discharge infrastructure). Major sustainability considerations unique to GAC systems are associated with:

- raw material collection and transportation

- GAC manufacturing and transportation

- larger media vessels relative to IX due to longer EBCTs

- larger treatment complex size due to larger vessels

- spent media transportation followed by reactivation, destruction, or disposal.

Multiple resources are available for performing sustainability assessments for sorption remedial designs (Amini et al. 2015; Choe et al. 2013; Choe et al. 2015; Dominguez-Ramos et al. 2014; Favara et al. 2016; Maul et al. 2014; Rahman et al. 2014; Ras and von Blottnitz 2012). Additional information is included in Section 12.9.

Related Past, Ongoing, and Recent Research Funded by SERDP:

- ER21-1185 Thermal Decomposition of Per- and Polyfluoroalkyl Substances on Granular Activated Carbon: Kinetics, Mass Balance, and Reuse of Reactivated Carbon

- ER21-1111 An Investigation of Factors Affecting In Situ PFAS Immobilization by Activated Carbon

- ER20-3034 Thermal Reactivation of Spent GAC from PFAS Remediation Sites

- ER19-5181 Improved Longevity and Selectivity of PFAS Groundwater Treatment Using Sub-Micron Powdered Activated Carbon and Ceramic Membrane Filter System

- ER22-7363 Rapid and Inexpensive Delivery of Particulate Carbon for In Situ PFAS Treatment in Groundwater

12.2.1.2 Ion Exchange Resin

Treatment Description: Ion exchange (IX) resin is an effective sorbent for other contaminants and has historically been used for a variety of water treatment applications (for example, nitrate, perchlorate, arsenic). To date, IX for PFAS removal from water is limited to ex situ applications.

IX resin options for removal of PFAS include single-use and regenerable resins. Single-use anion exchange resins are used until breakthrough occurs at a pre-established threshold and are then removed from the vessel and currently disposed of by high temperature incineration or by landfilling, where permitted. Regenerable resins are used until breakthrough but are then regenerated on site using a regenerant solution capable of returning a reduced capacity to the resin. Temporary and permanent IX systems can be rapidly deployed.

Treatment Mechanism: Removal of PFAS by IX is a physical mass transfer process from the aqueous phase onto solid media that does not involve any form of chemical degradation or transformation. IX resins with positively charged functional groups remove negatively charged PFAS from water by forming ionic bonds (the sulfonic and carboxylic acid heads of PFOS and PFOA are negatively charged at the typical range of pH values found in natural water). Simultaneously, the hydrophobic end of the PFAS structures can adsorb onto the hydrophobic surfaces of the IX resins, leading to increased ion exchange affinity on resins with hydrophobic backbones. Some PFAS at high liquid-phase concentrations (for example, 1 g/L) have been shown to also exhibit nonexchange sorption onto IX resins (Zaggia et al. 2016). However, the specific conditions and underlying mechanisms leading to this nonexchange sorption are not yet fully understood.

State of Development: Ion exchange technology has been used since the late 1930 for common water treatment processes like softening, demineralization, and selective contaminant removal. The development and use of selective resins for PFAS removal is relatively new but already well established. Single-use resins are now widely used for PFAS removal from water due to their simplicity of use and effectiveness in reducing regulated PFAS to nondetect (ND) levels. As of 2019, a limited number of regenerable IX systems have been installed in full-scale applications after successful pilot testing. Collection of data on longer term treatment and on-site regeneration of the IX resin is ongoing at a case study site (Section 15.2.2.2). In general, the removal capacity of the single-use resin is higher than that of regenerable resin, and single-use resin can be more fully exhausted in a lead-lag vessel configuration than regenerable resin. The relative removal efficiency of regenerable and single-use resins depends upon PFAS and co-contaminant influent concentrations and treatment goals.

Effectiveness: Selective IX has been demonstrated to reduce concentrations for a broad suite of PFAS at the bench and field scale for influent concentrations as high as 100s of parts per billion (ppb) total PFAS to below analytical detection limits in effluent (Kothawala et al. 2017; McCleaf et al. 2017; Woodard, Berry, and Newman 2017; Zeng et al. 2020). The affinity of such resin for common subgroups of PFAS generally follows the order PFSA > PFCA. Within each subgroup, affinity increases with increasing carbon chain length, and are not necessarily sequential (that is, longer chain PFCA may be adsorbed better than shorter chain PFSA).

In general, IX resin systems being used for PFAS removal are not installed with the intention of removing co-contaminants. Co-contaminants (including organic and inorganic compounds) may significantly reduce the removal capacity of IX for PFAS, although this depends on the selectivity of the IX resin. Because of the variability in resin behavior, as well as site-specific chemistry and co-contaminants, influent characterization is needed to assess potential pretreatment options to remove co-contaminants. Pretreatment is necessary to prevent fouling (for instance, by iron or manganese) and preserve resin capacity for PFAS removal, particularly in the context of remediation where complex co-contaminant chemistry is expected. Pretreatment needs for drinking water applications may be simpler or not required. Another consideration for drinking water utilities is that, depending on the type of IX resin used, a freshly installed IX column may cause short-term disruptions in pH or corrosivity of effluent water, which may necessitate mitigation strategies such as effluent blending or diverting initial effluent to waste (Smith et al. 2023).

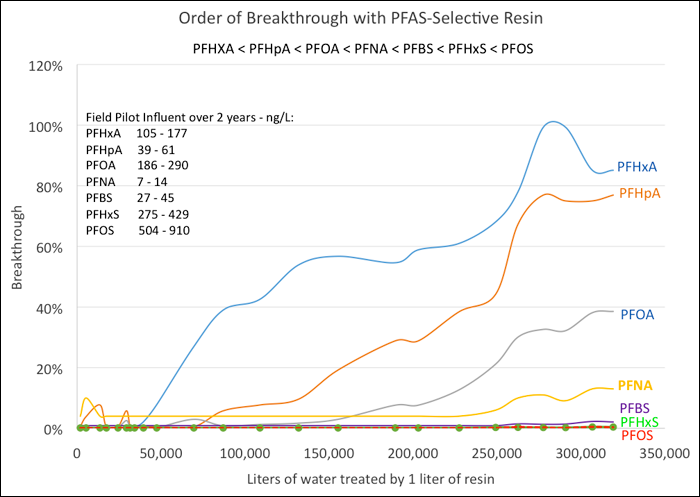

Single-use PFAS-selective IX resins are well-suited to treat low-concentration PFAS such as is typically encountered in potable water treatment systems, where media change-out would be infrequent. Figure 12-3 provides an example of removal curves and breakthrough information for a number of PFAS at the specified influent concentrations (in the legend) based on vendor-supplied data for a full-scale single-use system. Breakthrough is calculated as the ratio of the effluent concentration to the influent concentration (C/C0). It is not uncommon to observe fluctuations in the breakthrough curve in some field pilot studies due to varied influent concentrations over time. For example, after a resin unit is in equilibrium with one PFAS at an initially higher influent concentration, a lower concentration influent can desorb PFAS from the resin, resulting in breakthrough higher than 100%. The typical breakthrough order observed in Figure 12-3 is expected to be similar for various anion exchange resins, as relative ionic bond strengths and carbon chain lengths result in shorter chain PFCAs to longer chain PFCAs desorbing first, followed by shorter chain PFSAs to longer chain PFSAs. Similar responses also apply to GAC.

Figure 12-3. Example of IX removal curves from a field pilot study at specific influent concentrations (2.5-minute EBCT). (Note: Initial concentrations in ng/L or ppt.)

Figure 12-3. Example of IX removal curves from a field pilot study at specific influent concentrations (2.5-minute EBCT). (Note: Initial concentrations in ng/L or ppt.)

Source: Used with permission from Purolite Corporation.

Regenerable IX is not yet approved per NSF 61 for potable water treatment. Regenerable resins are better suited for removal of higher concentration PFAS where the savings realized from reusing the treatment media outweighs the cost of frequent replacement of nonregenerable media. Regenerable IX becomes more efficient than single-pass media when flow rate and concentration increase and RAOs go down, because these factors increase the frequency and volume of media change-outs for single-pass media. These factors also increase the regeneration demand; however, regeneration frequency can be extended by using larger vessels. Cost efficiency and viability of regenerable IX relative to single-use IX and GAC media are evaluated in ESTCP ER18-5015.

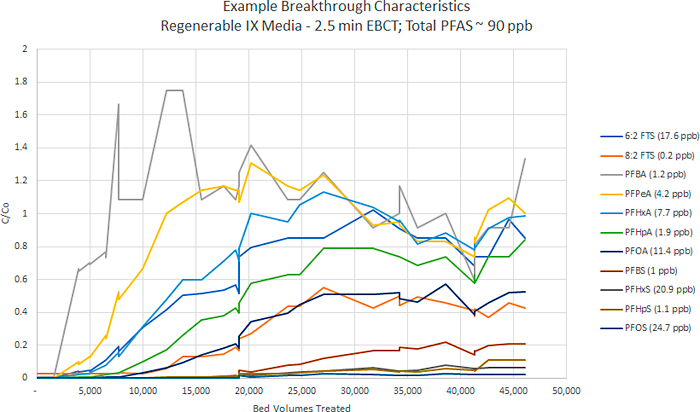

An example of typical breakthrough curves for regenerable resin system is shown in Figure 12-4. On the graph the y-axis is sample concentration/original concentration (C/Co), also note the influent PFAS concentrations (in the legend) in Figure 12-4 are higher (reported in ppb) than presented in Figure 12-3 (reported in ppt). Additional details on a regenerable resin system are provided in a case study in Section 15.2.2.2. The cost effectiveness for regenerable resin systems could increase significantly (and thus impact the system’s practical implementability) when a central regeneration facility can be shared amongst multiple PFAS removal systems. The application of single-use versus regenerable resins must be evaluated on a site-specific basis.

Figure 12-4. Example of regenerable IX removal curves from a field pilot study at specific influent concentrations (2.5-minute EBCT). (Note: Initial concentrations in µg/L or ppb.)

Figure 12-4. Example of regenerable IX removal curves from a field pilot study at specific influent concentrations (2.5-minute EBCT). (Note: Initial concentrations in µg/L or ppb.)

Source: Used with permission from ECT2.

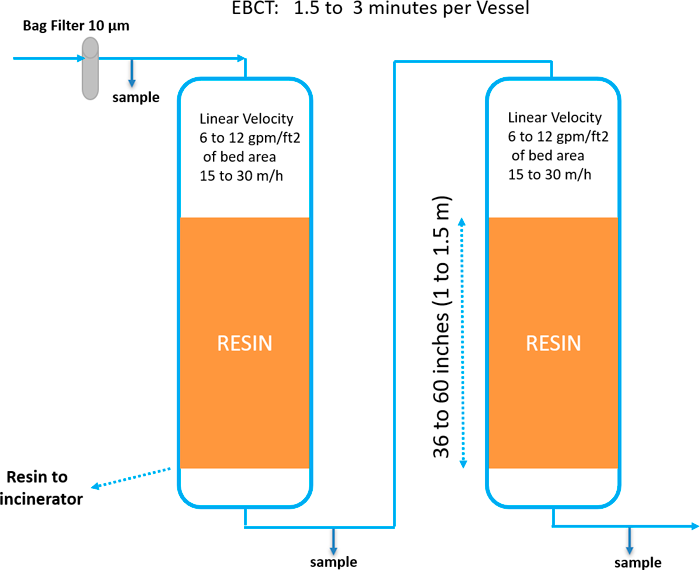

Design/Operating Considerations: IX treatment systems are configured similarly to GAC systems. Refer to Section 12.2.1 for a description of GAC systems that also applies to IX systems, and Section 12.2.1.2 for fouling considerations. Figure 12-5 depicts a simple process flow diagram for a single-use IX treatment system.

Figure 12-5. Single-use IX process flow diagram.

Figure 12-5. Single-use IX process flow diagram.

Source: Used with permission from Purolite Corporation.

Selective IX requires a relatively short EBCT of 1.5–5 minutes per vessel of resin (Boodoo 2017), hence smaller resin volumes and smaller, less costly treatment vessels versus GAC, which requires EBCTs of about 10–20 minutes per vessel (AWWA 2019; Brewer 2017) and correspondingly larger volumes of media. Selective IX resins have shown high operating capacities when removing trace levels of PFAS (for example, 100,000–400,000 bed volumes; refer to Figure 12-5), resulting in fewer change-outs of spent IX resin and reduced O&M costs. Capacity depends on the concentrations of competing anions, such as sulfate and nitrate, and on the specific PFAS breakpoint chosen for resin change-out. While lead-lag vessel design is standard, if space allows, it is possible to use a lead-lag-polisher design with three resin vessels in series. The addition of a polisher vessel provides a factor of safety for increasing the loading to the lead vessel, thereby reducing change-out frequency and cost. A lead-lag-polisher design will usually result in reduced operating expenses (OPEX) but higher capital expenses (CAPEX). Therefore, the decision to use it must be done on a case-by-case basis. Pretreatment may mitigate fouling and improve performance.

For drinking water supplies with relatively clean water, the industry is rapidly moving to rely more and more on vendor-provided modeling for common PFAS with such modeling including predicted breakthrough curves and resin capacities for specific PFAS breakpoints. Modeling can easily evaluate a variety of “what-if” scenarios, such as changing water chemistries and assessing the economics of operating to nondetectable levels or stricter regulatory limits for selected PFAS. Because of the USEPA (2022) health advisories and the USEPA proposed National Primary Drinking Water Regulations (NPDWRs) for MCL and MCLG values that are currently under public review (USEPA 2023), and the current inability of most labs to analyze to these low levels, modeling of treatment may be needed to evaluate how much faster theoretical breakthrough will occur and what extra cost will be incurred.

Pretreatment for several influent water parameters has been recommended (Section 12.2.1). Natural organic matter (NOM) is of particular importance because it occurs at concentrations that are three orders of magnitude higher than PFAS. Therefore, NOM can compete for the same ion exchange sites on the resin and can also blanket the surface of the resin beads, thereby blocking access for PFAS to the internal sites on the beads. The negative impact of NOM in groundwater on resin capacity can usually be factored in at the design stage if appropriate data and models are available, because NOM is usually present at less than 2 mg/L. However, when treating surface water with NOM concentrations that can seasonally rise to 5–10 mg/L (and even higher), it is particularly important to consider negative impact on resin capacity. Dixit et al. (2020) evaluated the impact of various dosages of Suwanee River NOM on resin capacity for PFAS and showed decreases of 22%, 50%, and 68% in resin capacity when adding dosages of 5, 10, and 20 mg/L NOM and using an organic scavenger acrylic resin in isotherm test solutions.

Despite the growing adoption of modeling, pilot testing is still recommended when evaluating breakthroughs for multiple PFAS or when the impact of TOC or other contaminants such as iron and manganese must be known to determine pretreatment requirements. In such cases, a technique referred to as accelerated piloting may be used, in which monitoring ports in the pilot column are set at 25%, 50%, and 100% of the resin height. This allows results to be obtained more quickly, but it is with the understanding that the breakthrough profile for each of the ports will be somewhat different. There is also growing interest in using the rapid small-scale column testing (RSSCT) technique for resins. Originally developed for use with GAC, the RSSCT technique uses crushed GAC and shorter EBCTs to quickly predict operating capacity. At this time, it is too early to know if this technique will reliably work for spherical resin beads when crushed.

Selective IX resins show much higher selectivity for PFAS than for common anions in water such as sulfate (SO42-), nitrate (NO3–), chloride (Cl–), and bicarbonate (HCO3–). However, these common anions are generally present in water at about three orders of magnitude higher than PFAS and will be the main competitors for the ion exchange sites on the resin. As such, they will largely determine the operating capacity of such resins. The choice between single-use and regenerable resins will in part be determined by the expected service period before the resin must be either replaced (single-use) or total regeneration costs (including capital and transportation costs). As PFAS concentration increases or as effluent criteria decreases, the frequency of regeneration or media change-out increases. As regeneration or media change-out increases, regenerable IX becomes more long-term cost-effective, if indeed the cost of regeneration is less than the cost of media replacement.

Regenerable IX resin can be reused long term if protected from contact with strong oxidizing agents, foulants, and chemical/mechanical stresses. In recent years, both pilot-scale and full-scale regenerable IX systems have demonstrated long-term durability of the media. One study, ESTCP ER18-5015, demonstrated greater than 95% removal capacity for regenerated media as compared to new media over six loading and regeneration cycles. IX regeneration is a chemical process. Field-demonstrated regeneration uses a solvent-brine solution in which the brine dislodges the ionic head of the PFAS molecule and the solvent desorbs the fluorinated carbon chain (or “tail”) from the IX resin (Woodard, Berry, and Newman 2017; Amec Foster Wheeler 2017). For a regenerable IX system, it is possible to concentrate the regenerant solution and reuse it by distillation (Nickelsen and Woodard 2017). The distillate residue then contains a concentrated PFAS waste that can be super-loaded onto specialized resin to create a small volume of solid waste that can be managed by off-site disposal or potentially through on-site destruction using other technologies currently under development and discussed in Table 12-1 Treatment Methods Table Excel File (for example, plasma or electrochemical destruction).

By combining various technologies in a treatment train approach, it may be possible to achieve better overall treatment at lower cost (Section 12.8).

Sustainability: Ex situ ion exchange water treatment systems have unique sustainability considerations in addition to those shared with other ex situ sorption media water treatment systems. Major sustainability considerations for ion exchange systems are associated with:

- raw materials, which are generally synthetic, petroleum derivatives

- resin manufacturing and transportation, including from overseas

- regeneration materials, energy, and labor for regenerable IX media

- disposal or destruction of regeneration residuals

- long-distance transportation of spent media to limited available disposal outlets

- energy-intensive destruction methods for spent media

Related Past, Ongoing, and Recent Research Funded by SERDP (ER) and Water Research Foundation (WRF):

- ER18-1027 Ex Situ Treatment of PFAS-Contaminated Groundwater Using Ion Exchange with Regeneration

- ER18-1063 Regenerable Resin Sorbent Technologies with Regenerant Solution Recycling for Sustainable Treatment of PFASs

- ER 18-5015 Removal and Destruction of PFAS and Co-Contaminants from Groundwater via Groundwater Extraction and Treatment with Ion-Exchange Media, and On-site Regeneration, Distillation, and Plasma Destruction

- ER 18-1306 Combined In Situ/Ex Situ Treatment Train for Remediation of Per- and Polyfluoroalkyl Substance (PFAS)-Contaminated Groundwater

- ER18-5053 Evaluation and Life Cycle Comparison of Ex Situ Treatment Technologies for Poly- and Perfluoroalkyl Substances in Groundwater

- WRF 4913 Investigation of Treatment Alternatives for Short-Chain PFAS

- ER20-5252 Anion Exchange Permeable Adsorptive Barriers (PABs) for In Situ PFAS Immobilization and Removal

- ER18-1320 Electrochemical Oxidation of Perfluoroalkyl Acids in Still Bottoms from Regeneration of Ion Exchange Resins

12.2.2 High-Pressure Membranes

In the context of this document, high-pressure membranes are defined as those meeting the characteristic separation performance of nanofiltration (NF) and reverse osmosis (RO) membranes. Both the NF and RO membrane categories span a range of selectivity (for example, loose NF to tight RO) and may rely on different rejection mechanisms to support the separation of PFAS from impacted water. However, under the correct application, both technologies have been proven to effectively remove PFAS from a variety of feed water sources. This technology is generally considered more applicable to high volume, low concentration liquids than low volume, high concentration liquids.

12.2.2.1 Nanofiltration (NF)

NF is a form of membrane technology that is pressure-driven and shown to be effective in the removal of PFAS (Tang et al. 2007). This method of filtration provides high water flux at low operating pressure (Izadpanah and Javidnia 2012). Typically, NF membranes exhibit high rejection of polyvalent ions and other molecules of sufficient size, but are susceptible to permeation by monovalent ions (for example, sodium, chloride) and smaller molecules. The most common membrane module configurations are spiral-wound (consisting of flat sheet membrane material wrapped around a central collection tube); however, hollow fiber NF modules may also be available for applications with higher fouling potential.

Available data on the removal of PFAS via NF consist of laboratory-scale tests performed on flat sheet membrane coupons (laboratory-scale sections of the membranes to be tested) and one full-scale drinking water treatment plant using an NF treatment train. Therefore, variations in performance due to fouling, flux, and concentration distributions in standard spiral-wound membrane configurations have not been characterized (Boo et al. 2018).

NF membranes tested include the DuPont (formerly Dow FilmTec) membranes NF-270, NF-200, and NF-90, and the SUEZ (formerly GE Water & Process Technologies) DK membrane. Reported rejections were generally > 95% for PFAS with molecular weights ranging from 214 grams per mole (g/mol) to 713 g/mol, though some compounds had lower rejections (PFPeA at 70% and perfluorooctane sulfonamide at 90%) (Steinle-Darling and Reinhard 2008; Appleman et al. 2013). Effective full-scale removal of PFAS by NF membranes was confirmed based on nondetectable PFAS concentrations (<4 ng/L) in NF permeate (Boiteux 2017). Salt passage for PFOS was reported to range from < 1% for the tighter NF-90 membrane to about 6% for the looser NF-270 and DK membranes (Tang et al. 2007). New research has focused on functionalizing membrane surfaces to improve PFAS selectivity (for example, Johnson et al. 2019). An appropriate disposal or treatment of the membrane concentrate stream needs to be considered, especially the application of high-pressure membranes for inland communities. Fluoropolymers may be used to manufacture membranes, which brings into consideration the need for PFAS-bearing reagents to manufacture the membranes, disposal of manufacturing byproducts, and disposal of spent filters.

12.2.2.2 Reverse Osmosis (RO)

RO is a technology used to remove a large majority of contaminants (including PFAS) from water by forcing water, under pressure, across a semipermeable membrane as described below. A typical RO system consists of three streams: the untreated water (feed), the treated water (permeate), and the residual reject water (concentrate). The most common membrane module configuration is spiral-wound, which consists of flat sheet membrane material wrapped around a central permeate collection tube. Like most treatment technologies, RO is seldom used alone, but rather as part of a treatment train. Most efficient RO performance may require pretreatment. RO-treated effluent (that is, permeate) may require supplemental management to mitigate the corrosivity of demineralized water.

Treatment Description: RO membranes are effective in removing most organic and inorganic compounds from water solutions. In recent years, new polymer chemistry and manufacturing processes have improved efficiency, lowering operating pressures and reducing operating costs (Lau et al. 2012). As a result, RO membranes are increasingly used by industry to concentrate or remove chemicals. RO is commonly used around the world in household drinking water purification systems, the production of bottled mineral water, self-contained water purification units (for example, for branches of the U.S. military), and industrial applications (for example, water supply to cooling towers, boilers, and deionized water). The largest application of RO is in desalination. In comparison, high-pressure membrane applications typically have higher capital and operating costs relative to GAC or IX systems designed for PFAS removal.

Treatment Mechanism: RO removes compounds from water solutions by forcing pressurized water across a semipermeable membrane. The driving pressure required in RO systems is a function of multiple factors, including the osmotic pressure of the feed water, the membrane type, and the system configuration. Typically, size exclusion is the prevailing mechanism for contaminant removal in RO membrane systems. The physical barrier (that is, semipermeable membrane) underlying the size exclusion removal mechanism provides additional assurance regarding the treatment of PFAS spanning a wide range of physical and chemical properties. Treated water (permeate) passes through the membrane and the rejected water (concentrate) is collected for disposal or discharge, depending on the nature of the compounds present.

State of Development: RO has been studied in bench-scale studies and pilot plants for wastewater and drinking water applications, offering the opportunity to compare both treatments operating simultaneously (Tang et al. 2006; Tang et al. 2007; Flores 2013; Glover, Quiñones, and Dickenson 2018; Dickenson 2016; Merino et al. 2016; Appleman 2014; Snyder 2007). This allows for an understanding of the effectiveness of traditional drinking and wastewater treatment methods alongside PFAS-specific technologies.

Effectiveness: Pretreatment is important when working with RO membranes. Membranes can be susceptible to fouling (loss of production capacity) because some accumulated material cannot be removed from the membrane surface during routine cleaning and maintenance procedures. Therefore, effective pretreatment to mitigate the formation of organic or inorganic foulants is a necessity for many RO systems. Pretreatment technologies would be specific to the RO feedwater quality.

RO removal of PFAS from various waters (for example, semiconductor wastewater, drinking water, surface water, and reclaimed water) has been studied and several studies have combined RO with nanofiltration (NF). PFOS removal > 99% was achieved using four different types of membranes over a wide range of feed concentrations (0.5–1,500 ppm [mg/L]) (Tang et al. 2006). Another study by Tang et al. (2007) tested five RO and three NF membranes at feed concentrations of 10 ppm PFOS over 4 days. The PFOS rejection and permeate flux performances were > 99% for RO and 90–99% for NF. The use of RO and NF as advanced drinking water treatments is still limited, but both technologies have been shown to be successful for the removal of longer chain (> C5) PFAAs (Loi-Brügger et al. 2008; Tang et al. 2006).

Thompson et al. (2011) studied the fate of perfluorinated sulfonic acids (PFSAs) and carboxylic acids (PFCAs) in two water reclamation plants that further treat water from wastewater treatment plants (WWTPs) in Australia. One plant (Plant A) used adsorption and filtration methods alongside ozonation; the other (Plant B) used membrane processes and an advanced oxidation process to produce purified recycled water. At both facilities, PFOS, perfluorohexane sulfonate (PFHxS), perfluorohexanoate (PFHxA), and PFOA were the most frequently detected PFAS. Comparing the two reclamation facilities, Plant A showed some removal during the adsorption/filtration stages. Overall, however, Plant A failed to completely remove PFOS and the PFCAs shorter than PFNA in chain length. All PFAS present were removed by RO at Plant B from the finished water to concentrations below detection and reporting limits (0.4–1.5 ng/L).

Design/Operating Considerations: This section refers to design and operating considerations for both RO and NF systems. Typical high-pressure membrane systems can achieve recoveries between 70% and 85%, with some high recovery applications able to achieve >95% recovery (Bond and Veerapaneni 2008; Stover 2013). Recovery is defined as the ratio of treated effluent (permeate) to feed water. The feed water not accounted for in the permeate is the reject or concentrate. In conventional systems, the concentrate fraction may represent 15%–30% of the feed flow or <5% of the feed flow for high recovery applications. In conventional or high recovery high-pressure membrane systems, recovery is typically limited by the feed water quality.

In the process of planning and implementing a high-pressure membrane filtration system, there are several important issues that affect system design and operation and could impact system performance and thus PFAS removal. These issues include membrane flux, water quality, and temperature.

- Membrane Flux: One of the major challenges in the application of membrane technology is fouling (significant flux loss due to continuous accumulation of colloidal and organic matter, precipitation of inorganic salts, and/or microbial growth). There are several ways to mitigate fouling: (1) changing operating conditions, (2) modifying the membrane, and (3) modifying the feed by adding antifoulants prior to filtration system (pretreatment) (Roux et al. 2005). Adequate pretreatment and appropriate membrane selection can slow the fouling rate, but routine membrane cleaning is an essential step in maintaining the performance of the membrane process. Membrane replacement is a necessary part of plant operation to maintain the quality of the produced water (Abdul-Kareem Al-Sofi 2001). Although there are a number of cleaning techniques, such as physical or chemical or a combination of both, chemical cleaning methods are more widely used by NF and RO industries for membrane cleaning and regeneration. Spent cleaning solution may contain PFAS and would need to be managed properly.

- Water Quality: Because water quality can have a significant impact on membrane flux, feedwater quality is also a primary design consideration for membrane filtration systems. Poorer water quality (high suspended and dissolved solids, co-contaminants) will reduce flux, which in turn increase the necessary membrane area and required number of membrane modules, adding to both the cost and the size of the system. However, pretreatment can often improve feedwater quality at a lower cost than additional membrane area. Because RO is a relatively expensive technology, efforts to improve water quality with pretreatment processes ahead of the RO membranes (filtration, precipitation; see Section 12.7) will result in reduced capital and operating costs.

- Temperature: Like other water quality parameters such as turbidity and total dissolved solids (TDS) (for NF/RO systems), the temperature of the feedwater also affects the flux of a membrane filtration system. Water becomes increasingly viscous at lower temperatures; thus, lower temperatures reduce the flux across the membrane at constant transmembrane pressure or alternatively require an increase in pressure to maintain constant flux. Because rejection decreases as membrane pores expand at higher temperatures, more permeation of PFAS across the membrane could occur at higher operating temperatures.

Sustainability: The environmental footprint for this technology includes energy source and consumption during treatment system operation, as well as manufacturing/disposal of pretreatment/treatment media (examples may include solids from upstream precipitation/coagulation or microfiltration, used cartridge filters, and worn RO membrane modules) and cleaning solutions to maintain the membrane. RO requires power for high-pressure pumps and the management of concentrate, which can be energy intensive.

An issue inherent to contaminant removal by membrane processes is the disposal of the PFAS-enriched concentrate, which must be carefully considered. Development of effective treatment methods for the concentrate entails evaluating significant parameters, such as volume generated, concentration, characteristics of the feedwater, and operational conditions, and using well-verified analytical methods to detect trace amounts of contaminants. Concentrate treatment and management alternatives remain an active area of research (Joo and Tansel 2015). Tow et al. (2021) documented treatment and management alternatives specifically focused on PFAS-impacted concentrates. Tow et al. (2021) reviewed 22 different PFAS-impacted concentrate treatment or management alternatives that included application of additional separation technologies (for example, adsorbents, foam fractionation), destructive technologies, and disposal/sequestration options. There are numerous options to consider for PFAS-impacted concentrate treatment and/or management, and identifying the best alternative will be a function of site-specific factors including location, volume of concentrate, PFAS concentrations, and presence of co-contaminants.

12.2.3 Foam Fractionation

Treatment Description: Foam fractionation is a subset of a larger treatment of practice known as adsorptive bubble separation technologies. Foam fractionation is a physical separation process that traditionally uses air and turbulence to generate bubbles rising through a water column to strip amphiphilic substances such as PFAS from the bulk liquid (Lemlich and Lavi 1961; Lemlich 1972). Foam fractionation technology has been used for decades in the commercial-scale aquarium business to clean water by separating and removing proteinaceous waste and has been advanced to multistage configurations for PFAS separation and concentration. Amphiphilic PFAS adsorb to the surface of the bubbles as they rise upwards. PFAS that accumulate at the top of the column as a concentrated foamate are then removed for further treatment or disposal. This process has been implemented for ex situ water treatment, and in situ, down-hole foam fractionation approaches have also been tested but are in less developed stages.

Treatment Mechanism: Air or other gaseous bubbles are introduced into a PFAS-containing liquid, which causes amphiphilic PFAS and other amphiphilic organic compounds to adsorb to the bubble surface, separating them from the bulk water. As the bubbles migrate upwards, PFAS are removed from the bulk liquid. The top foamate layer is concentrated in PFAS and can be removed passively via overflow or actively via vacuum suction for further treatment. The extent to and rate at which PFAS are removed depends on individual PFAS physical chemical properties, background water quality properties, and operational considerations discussed in the subsequent sections. Buckley et al. (2021) presented a detailed review, including description of key separation mechanisms, of foam fractionation for water treatment. Stevenson and Li (2014) produced a monograph on the theory and practical implementation of foam fractionation.

State of Development: Foam fractionation has been studied at the bench scale and implemented at the pilot- and full-scale level to remove PFAS in groundwater (Burns et al. 2021) leachate (Burns et al. 2022; Newman 2022; Smith et al. 2022; McCleaf et al. 2021; Robey et al. 2020), and industrial water (Smith et al. 2023). The base technology was developed and built in Australia and is currently operating at full-scale in Queensland, Australia (see the case study in Section 15.2.4.1 and Burns et al. (2021). Foam fractionation systems have successfully removed PFOS and PFOA to low level parts per trillion levels (Burns et al. 2021; Burns et al. 2022; Newman 2022; Smith et al. 2022; Smith et al. 2023). Additional research is underway to promote removal of short-chain PFAS such as PFBA and PFBS in foam fractionation, which to date have not been effectively removed across all waters tested. Short-chain carboxylates have proven especially difficult to remove. Foam fractionation is provided by multiple commercial vendors in the United States, Europe, Canada, and Australia. Maximum flow rates implemented in the field are on the order of 50–150 gallons per minute in single fractionators. Scale up to larger foam fractionators is theoretically feasible, and multiple fractionators in parallel have been deployed to treat higher flow rates.

Effectiveness: Foam fractionation is highly effective at removing PFOS and PFOA and longer chain PFAS (Burns et al. 2021; Newman 2022; Burns et al. 2022; Smith et al. 2022) to single-digit parts per trillion levels, but its performance at removing PFAS with fewer than six perfluorinated carbons remains mixed. Removal of PFAS during foam fractionation is dependent upon individual PFAS adsorption coefficients (Burns et al. 2022), which are derived from the adsorption isotherm under specific conditions for each compound for uptake onto a gas/liquid interface. As with adsorptive media, perfluoroalkyl sulfonates of an equivalent perfluoroalkyl chain length are removed during foam fractionation more effectively than perfluoroalkyl carboxylates (for example, PFHxS is removed more effectively than PFHpA). Researchers and practitioners have identified that chemical additions, often in the form of cationic surfactants, can improve the removal of PFBS, PFHxA, PFPeA, and PFBA (Buckley et al. 2022; Newman 2022; Buckley et al. 2023; Vo et al. 2023). A cationic surfactant that successfully removed PFBA in a deionized solution of sodium chloride was unable to remove PFBA from landfill leachate under similar operating conditions (Buckley et al. 2023; Vo et al. 2023). Foam fractionation is also effective at removing a wide range of PFAS concentrations (for example, nanograms per liter to milligrams per liter); however, greater orders of magnitude removal require longer hydraulic retention times and/or additional stages of treatment.

Foam fractionation can also be effective for PFAS removal on a wide range of water quality types without the need for additional pretreatment. The complexity of the leachate matrix is likely one reason why foam fractionation has been trialed so extensively on leachate (Burns et al. 2022; Newman 2022; Smith et al. 2022; McCleaf et al. 2021; Robey et al. 2020). Compared to PFAS treatment with GAC, anion exchange resin, and reverse osmosis, foam fractionation performance is impacted in a much more limited way by background analytes such as TOC, dissolved metals, and hardness that foul adsorptive media and membranes. The primary constituents that concentrate into the foamate through a foam fractionation process are suspended solids, PFAS, and other surfactants, including any used to enhance the foaming process, while other water quality characteristics such as dissolved anions and cations remain similar in concentration to the source water. See the case study in Section 15.2.4.2.

Site-specific water chemistry does impact foam fractionation performance, so laboratory testing is recommended to optimize pilot design. Some researchers have reported a higher degree of removal during foam fractionation as TDS increases in the source water (Buckley et al. 2022).

Design/Operating Considerations: Design parameters that can affect the performance of ex situ foam fractionators include the following:

- The non-PFAS characteristics of the water, including constituents that can increase or diminish the natural foaming potential of the water

- The hydraulic retention time of the fractionator; hydraulic retention times reported in the literature for stripping fractionators have typically fallen within the range of 10–60 minutes (Smith et al. 2022; Buckley et al. 2022; Newman 2022)

- Countercurrent or co-current flow of gas and water

- The amount, speed, and bubble size of gas introduced per volume of water in the fractionator. The bubble size is partially related to the type of gas introduced, with ozone bubbles typically introduced with a smaller size than air.

- The amount of turbulence introduced along with the gas. More turbulence tends to increase foam generation and has an overall beneficial impact on PFAS removal

- The height of the water column relative to the foam collection point (that is, a weir or overflow)

- The mechanism of foamate removal, which can include traditional spillover or application of a vacuum process

- The number of treatment units operated in series

- Batch, semicontinuous batch, or continuous flow operation, which is discussed in more detail below

- The introduction of chemical agents to increase foaming or removal of particular PFAS